The day eventually came round, when we decided to remove the mold...After all this work over such a long time... I had forgotten what we had actually done...

As luck would have it, some of my sons friends arrived out of the blue...they would come in handy...

It was'nt very pretty, but the way to start to release the mold... is to hammer it on all surfaces with a rubber mallet.

After this,a wedge of wood was partially forced between the two surfaces to force them apart...after doing this a few times the mold slightly lifted from the boat...

It was'nt until a length of strong rope was fixed to the nose of the mold and then levered against the bow,(using a six foot length of 3x3in) of the boat underneath...that there was a series of cracks..and the mold broke free...

Everybody then managed to get their fingers in between the two surfaces, and lifted..

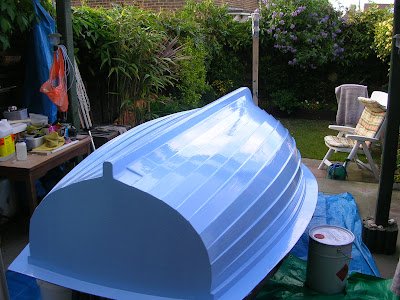

There it was in all it's glory...The Mold...

It looked great....a few little blemishes here and there, but nothing to really bother about...the 10 coats of wax had done their job.

This called for a beer...in fact beers all round...